1. DLLA145P1581 Diesel Injector Nozzle Application Information 1.DLLA145P1581 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / 2.DLLA145P1581 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA145P1581 Injector Nozzle Part… Read More »Common Rail Diesel DLLA145P1581 Injector Nozzle.Encyclopedia

Categories

CONTACT US

Tag

-

109-1025 injector nozzle promotion -

M0008P155 fuel injector nozzle blog -

L136PBD injector nozzle promotion -

injector nozzle L322PBC blog -

injector nozzle M0008P155 blog -

injector nozzle 109-1025 blog -

L322PBC injector nozzle promotion -

375GHR common rail diesel injector nozzle news -

M0008P155 injector nozzle promotion -

375GHR common rail injector nozzle news -

DLLA128P2198 common rail diesel injector nozzle blog -

375GHR fuel injector nozzle news -

DLLA128P2198 common rail injector nozzle blog -

injector nozzle 375GHR news -

DLLA128P2198 fuel injector nozzle blog -

375GHR injector nozzle promotion -

L136PBD injector nozzle blog -

L097PBD common rail diesel injector nozzle blog -

G3S33 common rail diesel injector nozzle blog -

injector nozzle DLLA128P2198 blog -

109-1025 injector nozzle blog -

L136PBD common rail diesel injector nozzle blog -

G3S33 common rail injector nozzle blog -

109-1025 common rail diesel injector nozzle blog -

L136PBD common rail injector nozzle blog -

L322PBC common rail diesel injector nozzle blog -

G3S33 fuel injector nozzle blog -

M0008P155 common rail diesel injector nozzle blog -

109-1025 common rail injector nozzle blog -

L136PBD fuel injector nozzle blog

Hot News

1. DLLA151P2488 Diesel Injector Nozzle Application Information DLLA151P2488 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure 0 445 110 691 CRI1-16 1600 / / 0 445 111 016 CRI1-16 / / / DLLA151P2488 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE… Read More »Common Rail Diesel DLLA151P2488 Injector Nozzle.Encyclopedia

1. DLLA151P2488 Diesel Injector Nozzle Application Information DLLA151P2488 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure 0 445 110 691 CRI1-16 1600 / / 0 445 111 016 CRI1-16 / / / DLLA151P2488 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE… Read More »Common Rail Diesel DLLA151P2488 Injector Nozzle.Encyclopedia

1. DLLA151P2479 Diesel Injector Nozzle Application Information DLLA151P2479 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2479 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2479 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2479 Injector Nozzle.Encyclopedia

1. DLLA151P2479 Diesel Injector Nozzle Application Information DLLA151P2479 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2479 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2479 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2479 Injector Nozzle.Encyclopedia

1. DLLA151P2421 Diesel Injector Nozzle Application Information DLLA151P2421 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2421 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2421 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2421 Injector Nozzle.Encyclopedia

1. DLLA151P2421 Diesel Injector Nozzle Application Information DLLA151P2421 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2421 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2421 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2421 Injector Nozzle.Encyclopedia

1. DLLA153P2639 Diesel Injector Nozzle Application Information DLLA153P2639 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA153P2639 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA153P2639 Injector Nozzle Part Number… Read More »Common Rail Diesel DLLA153P2639 Injector Nozzle.Encyclopedia

1. DLLA153P2639 Diesel Injector Nozzle Application Information DLLA153P2639 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA153P2639 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA153P2639 Injector Nozzle Part Number… Read More »Common Rail Diesel DLLA153P2639 Injector Nozzle.Encyclopedia

1. DLLA147P2619 Diesel Injector Nozzle Application Information 1. DLLA147P2619Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / 2. DLLA147P2619 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA147P2619 Injector Nozzle Part Number… Read More »Common Rail Diesel DLLA147P2619 Injector Nozzle.Encyclopedia

1. DLLA147P2619 Diesel Injector Nozzle Application Information 1. DLLA147P2619Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / 2. DLLA147P2619 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA147P2619 Injector Nozzle Part Number… Read More »Common Rail Diesel DLLA147P2619 Injector Nozzle.Encyclopedia

1. DLLA150P2272 Diesel Injector Nozzle Application Information DLLA150P2272 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure 0 445 110 454 CRI2-16 1600 / / DLLA150P2272 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number 0 445 110 454 / 11112100ABA /… Read More »Common Rail Diesel DLLA150P2272 Injector Nozzle.Encyclopedia

1. DLLA150P2272 Diesel Injector Nozzle Application Information DLLA150P2272 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure 0 445 110 454 CRI2-16 1600 / / DLLA150P2272 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number 0 445 110 454 / 11112100ABA /… Read More »Common Rail Diesel DLLA150P2272 Injector Nozzle.Encyclopedia

1. L242PBC Diesel Injector Nozzle Application Information L242PBC Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Replace Part Number OEM OEM / / / / L242PBC Diesel Injector Nozzle Car Model Matching Information Car Number Manufactured / / 2. L242PBC Injector Nozzle Part Number Common Writing L242PBC,242PBC,242,L242 3. L242PBC Diesel Injector Nozzle Technical Support L242PBC Diesel Injector Nozzle Installation Precautions Clean the injector… Read More »Common Rail Diesel L242PBC Injector Nozzle Encyclopedia

1. L242PBC Diesel Injector Nozzle Application Information L242PBC Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Replace Part Number OEM OEM / / / / L242PBC Diesel Injector Nozzle Car Model Matching Information Car Number Manufactured / / 2. L242PBC Injector Nozzle Part Number Common Writing L242PBC,242PBC,242,L242 3. L242PBC Diesel Injector Nozzle Technical Support L242PBC Diesel Injector Nozzle Installation Precautions Clean the injector… Read More »Common Rail Diesel L242PBC Injector Nozzle Encyclopedia

1. DLLA152P2666 Diesel Injector Nozzle Application Information 1.DLLA152P2666 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / 2.DLLA152P2666 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA152P2666 Injector Nozzle Part… Read More »Common Rail Diesel DLLA152P2666 Injector Nozzle.Encyclopedia

1. DLLA152P2666 Diesel Injector Nozzle Application Information 1.DLLA152P2666 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / 2.DLLA152P2666 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA152P2666 Injector Nozzle Part… Read More »Common Rail Diesel DLLA152P2666 Injector Nozzle.Encyclopedia

1. DLLA151P2407 Diesel Injector Nozzle Application Information DLLA151P2407 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2407 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2407 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2407 Injector Nozzle.Encyclopedia

1. DLLA151P2407 Diesel Injector Nozzle Application Information DLLA151P2407 Diesel Injector Nozzle Application for Injectors Part Number Injector Part Number Injector Series System Pressure Re-manufactured Part Number System Pressure / / / / / DLLA151P2407 Diesel Injector Nozzle Car Model Matching Information Injector Part Number Car Number OE Number OE Number OE Number / / / / / 2. DLLA151P2407 Injector Nozzle Part Number Common… Read More »Common Rail Diesel DLLA151P2407 Injector Nozzle.Encyclopedia

1. DLLA151P2407 Diesel Injector Nozzle Application Information

DLLA151P2407 Diesel Injector Nozzle Application for Injectors Part Number

| Injector

Part Number |

Injector Series | System Pressure | Re-manufactured Part Number | System Pressure |

| / | / | / | / | / |

DLLA151P2407 Diesel Injector Nozzle Car Model Matching Information

| Injector Part Number | Car Number | OE Number | OE Number | OE Number |

| / | / | / | / | / |

2. DLLA151P2407 Injector Nozzle Part Number Common Writing

0433172407,DLLA151P2407,0 433 172 407,DLLA 151 P 2407,0433 172 407,DLLA151 P 2407,0433172 407,DLLA151P 2407,0 433 172407,DLLA151 P2407,0 433172407,DLLA 151P2407,0 433172 407,DLLA 151P 2407

3. DLLA151P2407 Diesel Injector Nozzle Technical Support

1.DLLA151P2407 Diesel Injector Nozzle Installation Precautions

1) Clean the injector nozzle in an ultrasonic cleaner for 3-5 minutes before installation, so as to make the stains, dust, rust-proof oil oxides, paraffin base, naphthenic base, intermediate base, salt, lead naphthenate, zinc naphthenate, sodium petroleum sulfonate, barium petroleum sulfonate, calcium petroleum sulfonate, tallow diamine trioleate, rosinamine on the surface of the injector nozzle fall off.

2) Use compressed air to clean the cleaning fluid attached to the surface of the injector nozzle after cleaning, and clean it up to the standard of use.

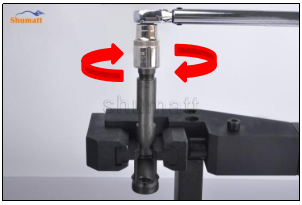

2.DLLA151P2407 Diesel Injector Nozzle Installation

1) Tightening torque of injector nozzle

The torque lever and tightening moment specified in the injector maintenance manual must be installed when the injector nozzle is installed. (50Nm)

The tightening torque of the nozzle cap must be installed in accordance with the tightening torque specified in the injector maintenance manual

4. DLLA151P2407 Injector Nozzle Testing After Maintenance

1.After installation, it needs to be tested on the test bench.

The correct injector type should be selected for testing

2.The test results need to be ensured that the following items are within the standard data range of the test stand.

LEAK TEST: Test whether sealing test is up to standard or not

In this step, no injector collector should be installed at the nozzle during the test so as to observe whether the nozzle is dripping oil, meanwhile observe that all joints are no oil leaking.

The static oil return of the test should not exceed 8mm2/H, otherwise, you need to check whether the high-pressure sealing ring, valve assembly, and stroke parameters of the injector are within the standard range.

VL: Test whether full load oil (main injection, high speed) is up to standard or not

This step needs to be combined with vehicle driving conditions, such as power, fuel consumption and smoke as well as the maintenance of the engine, if there is situation of insufficient power, fuel consumption is high, thick black smoke and irregularly maintenance of the engine, the engine needs to be maintained according to the maintenance handbook at very first time.

Each of injector part needs to be adjusted and checked if there is any damage according to above situations to ensure the injector is normal. After make sure the injector works normal, you need to reduce the armature stroke if too much oil injection, and increase the armature stroke if too little oil injection.

The error of each injector should be controlled in 6mm3/HH when adjusting.

TL\EM: Test whether the torque point, emission point, exhaust limit, fuel supply reach standard or not

Through this test, it is detected that when the oil injection is too little, the engine’s acceleration is slow, vice versa, when the oil injection is too much, the engine’s acceleration will produce black smoke and the engine excessive exhaust emissions.

Injector nozzle spring force gasket, armature stroke, lift gasket and solenoid valve spring force gasket determine whether exhaust restriction and injector fuel supply reach standard

LL: Test if the idle fuel supply reaches the standard

This test detects oil injection is too much will cause engine idle smoke, otherwise if the oil injection too little will cause engine idling easy to stall, or difficult to start.

The uneven of oil injection causes the unstable rotation speed of engine , making noise, and increase the engine swing in the acceleration process.

Each injector error should be controlled within 2mm3/HH when adjusting.

Idle speed fuel supply quantity mainly by adjusting the nozzle spring force gasket.

VE: Test whether the pre-injection meets the standard

This test detects when oil injection is too much will cause cylinder knocking while the engine is working and the exhaust emissions is not up to standard (smoke).

While when oil injection is too little will cause big noise while the engine is working, the engine is difficult to start, the engine weak acceleration, slow response of injector.

Each injector error should be controlled within 0.5mm3/HH when adjusting.

5. Copyright Statement

The text, pictures, web page layout design, logo, etc in the file “DLLA151P2407 Diesel Injector Nozzle Encyclopedia” are belong to this website and Shenzhen Shumatt Technology Co., Ltd.

Visitors can not use the content or services provided by in the file “DLLA151P2407 Diesel Injector Nozzle Encyclopedia” to reproduce, extract or use the above works in other ways. Those who have authorized the “DLLA151P2407 Diesel Injector Nozzle Encyclopedia” on this website should use them within the scope of authorization, and indicate the source of www.dieselinjectornozzles.com. Anyone who violates the above statement will be investigated for relevant legal responsibilities on this website

Any other questions to use this file, please contact us through hison@shumatt.com.